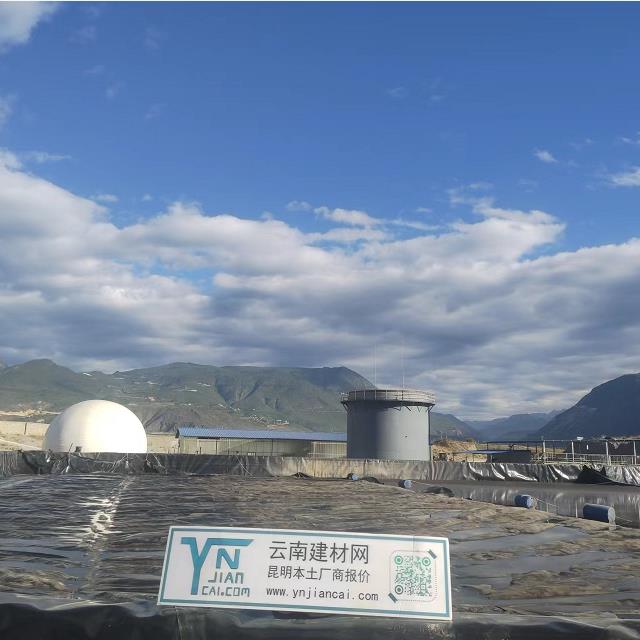

The construction site is located at the junction of Shangri-La and Lijiang. It is a large domestic breeding enterprise, Zhengbang Group. The purpose of this construction is that the biogas pool will emit a lot of odor. Therefore, the treatment method is to cover the surface of the pool with a layer of geomembrane to prevent the odor from overflowing.

The entire ground area of the biogas pool is 4000㎡. Therefore, if you want to make a cover for it, you need to weld a membrane material of more than 4000㎡. The only difficulty for the construction is that there is still biogas in the biogas pool, so you can't enter the pool for construction. The method we adopted is to weld outside the site. There is a 6.5M wide site around the biogas pool. Our construction is carried out in this site.

For the coverage of the biogas pool, we usually use floating barrels for auxiliary construction. When laying, it is not completed by welding at one time, and then dragging the whole sheet, but welding one sheet and dragging one sheet. Although this construction operation method is time-consuming, it can prevent the membrane material from being torn to a large extent.

The material used in this construction site is 1.5mm thick HDPE geomembrane. The construction took a total of 11 days. The area used for storing biogas slurry at the bottom of the pool is 3,650 square meters, and the cover of the biogas slurry pool is 3,900 square meters, totaling 7,550 square meters. Using geomembrane as a covering layer is different from our usual construction. For this site, the biggest difficulty is that the membrane material needs to climb over the pool wall about 2 meters high, which caused great trouble to the construction. Therefore, we also found a loader to assist in the entire laying process. There were not many construction workers this time, including welding technicians, the total number of workers was 6.

" />

" />