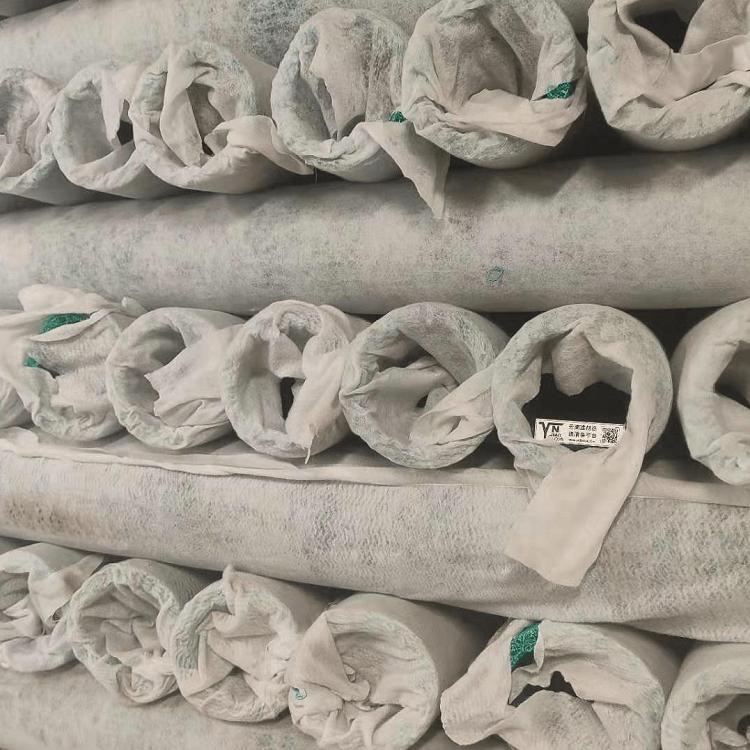

Plastic Blind Drainage Pipe** includes a layer of geotextile fabric and the pipe itself, with a standard length of 4 meters.

If the specifications you need are not listed above, you can choose others and provide details in the remarks section.

Plastic Blind Drainage Pipe Introduction:

Plastic blind drainage pipes are composed of a plastic core wrapped in filter fabric. The plastic core is made from thermoplastic synthetic resin as the primary material, modified, and extruded into fine plastic filaments under a molten state. These filaments are then fused at the junctions using a forming device to create a three-dimensional mesh structure. Currently, plastic cores come in various structural forms, such as rectangular, hollow matrix, circular, and hollow circular. This material overcomes the disadvantages of traditional blind drains and features high surface opening rate, good water collection ability, large porosity, excellent drainage, strong compressive resistance, good pressure resistance, flexibility, adaptability to soil deformation, durability, lightweight, ease of construction, significantly reduced labor intensity, and high construction efficiency. Therefore, it is widely accepted and applied in engineering projects.

Plastic Blind Drainage Pipe Features:

- No Adhesive Used: Since it is formed by hot-melt methods without using adhesives, it will not degrade or peel due to adhesive aging or separation, thus avoiding collapse.

- High Void Ratio: The three-dimensional structure has a void ratio of 80-95%, with a strong compressive performance that is 10 times stronger than resin pipes. Even under excessive pressure, the remaining voids remain above 50%, ensuring there is no blockage, and it will not be crushed by soil pressure.

- Compressive Strength and Flexibility: It is compressive and flexible, making it suitable for curves and bends during installation. It is very lightweight, and can be backfilled with a bulldozer if the fill depth is around 10 cm.

- Low Compression Rate: Under a pressure of 250 KPa, the compression rate is less than 10%.

- Durability: It is resistant to aging and can maintain stability even when placed underwater, in soil, or other harsh conditions for decades.

- Prevention of Common Issues: This material solves common issues of traditional blind drains, such as uneven settlement or blockage caused by overload, and prevents failure due to crushed voids.

- Structure and Water Absorption: The composition of the fibers forms a three-dimensional mesh structure. The surface opening rate is 95-97%, more than five times that of perforated pipes, and three to four times that of resin mesh pipes. The surface water absorption rate is extremely high.

Applications of Plastic Blind Drainage Pipes:

- Sports Fields: Golf courses, baseball fields, football fields, parks, and other green spaces for drainage.

- Rooftop Gardens and Flower Beds: Drainage systems for rooftop gardens and flower beds.

- Construction Foundation Projects: Drainage systems for building foundation works.

- Agriculture and Horticulture: Underground irrigation and drainage systems.

- Low-lying Wetlands: Drainage systems for low-lying, damp areas and land reclamation projects.

- Road and Railway Base Reinforcement: Drainage for the reinforcement of road and railway shoulders.

- Tunnels and Subways: Drainage systems for tunnels, subways, and underground warehouses.

- Slope and Embankment Development: Water and soil conservation for sloped land and embankment development.

- Retaining Walls: Vertical and horizontal drainage at retaining walls.

- Landslide Areas: Drainage for landslide-prone areas.

- Power Plants: Drainage for ash piles at thermal power plants, and landfill drainage.

Specifications for Circular Type:

| Model |

≥ 50mm |

≥ 80mm |

≥ 100mm |

≥ 150mm |

≥ 200mm |

| Hollow Size |

≥ 30mm |

≥ 50mm |

≥ 60mm |

≥ 90mm |

≥ 140mm |

| Weight (g/m) |

≥ 320 |

≥ 750 |

≥ 1000 |

≥ 1500 |

≥ 2500 |

| Void Ratio (%) |

≥ 75 |

≥ 80 |

≥ 80 |

≥ 80 |

≥ 80 |

| Compressive Strength (kPa) |

Flatness 5% ≥ 85 |

75 |

65 |

50 |

45 |

| Flatness 10% ≥ |

170 |

140 |

110 |

80 |

70 |

| Flatness 15% ≥ |

210 |

160 |

160 |

100 |

90 |

Specifications for Rectangular Type:

| Model |

≥ 70*35mm |

≥ 120*35mm |

| Hollow Size |

≥ 70*10mm |

≥ 40102mm |

| Weight (g/m) |

≥ 430 |

≥ 430 |

| Void Ratio (%) |

≥ 82 |

≥ 82 |

| Compressive Strength (kPa) |

Flatness 5% ≥ 70 |

60 |

| Flatness 10% ≥ |

100 |

90 |

| Flatness 15% ≥ |

160 |

130 |

| Flatness 15% ≥ |

220 |

180 |

" />

" />