" />

" />【 WeChat QR code consultation 】

13698775878

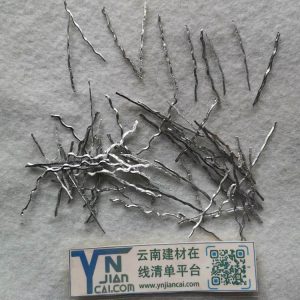

The commonly used models of steel fibers are the **shear wave shape and cold-drawn hooked-end**. The tensile strength of these two models are 300 MPa and 600 MPa, respectively. If the specifications you need are not listed above, you can select "Other" and provide further details in the remarks.

Steel fiber is a new, high-performance steel fiber variety. The mix design method of steel fiber roads is generally the same as that of ordinary concrete, with the following differences: dual strength control standards (compressive strength and flexural strength); steel fiber dosage is determined according to the flexural strength required by the design; unit water consumption and sand ratio are related to fiber dosage. For every 0.5% (volume rate) of steel fiber added, the unit water consumption increases by 6kg and the sand ratio increases by 2%.

Steel fiber concrete has the same mixing, operation and construction performance as ordinary concrete. The fibers will not ball up in the concrete and are evenly distributed. It can be produced in commercial concrete mixing plants and can be used for pumping construction. The early slump loss of milled steel fiber concrete is large, with a loss of 32% in 30 minutes and a loss of 42% in 2 hours. The actual workability of steel fiber concrete is better than that of ordinary concrete with the same slump. Steel fiber concrete has good material properties. Compared with ordinary concrete, its compressive strength is increased by 2-20%; flexural strength is increased by 20-50%; splitting tensile strength is increased by 20-40%; wear resistance is increased by about 40%. Its physical and mechanical properties can fully meet the technical indicators required by supporting components such as urban road projects and inspection well covers. The rough and clean surface of steel fiber can be firmly combined with the cement paste in concrete. This is the fundamental reason why milling steel fiber improves various properties of concrete.

In addition, high-strength steel fiber concrete has been widely used in prefabrication, cast-in-place, production and construction of railway sleepers, highway expansion joints, cement concrete pavements, etc. Its excellent performance can fully achieve good technical, economic and social environmental benefits.

1. Adhesion

Since the interface bonding between steel fiber and concrete matrix is mainly physical, that is, the transmission of friction shear force is the main factor, so for steel fiber itself, its bonding properties should be improved from two aspects: fiber surface and fiber shape. There are four specific methods.

1. Make the surface of steel fiber rough and the cross section irregular. This goal can be achieved by using the melt extraction method. Because when the steel fiber is rapidly cooled by air, the surface shrinks unevenly and becomes rough, and the cross section also shrinks into a crescent shape, increasing the contact area with the substrate. The milling type steel fiber has one smooth surface and the other rough surface, which also increases the contact area with the concrete.

2. Plastic processing is performed on the fiber at a certain interval along the axis of the steel fiber. For example, the "Xin Ke" steel fiber of Kobe Steel, Japan, the "XOREX" steel fiber of Raybond, USA (Figure 2-1, c), and the "S-2" and "S-3" steel fibers of Qing'an Steel Plant. Because the surface is pressed into a prism or a waveform, the mechanical bonding force is increased.

3. The two ends of the steel fiber are shaped differently. For example, the ingot milling type steel fiber has anchoring platforms at both ends; the "DRAM Ⅸ" steel fiber (Figure 2-1, e) of Becker Public Company in the United States and the "S-4' and as-so type steel fibers of Qing'an Iron and Steel Plant are all made into hooks at both ends; there are also large-headed steel fibers extracted by melting extraction. Due to the anchoring effect at both ends, the pull-out resistance is improved.

4. Coat the surface of the steel fiber with epoxy resin and treat the surface with micro-rusting. This method does not improve the interface bonding strength as well as the previous methods, but it also has a certain strengthening effect.

2. Hardness

No matter which processing method is used to manufacture the steel fiber, it will encounter high heat and rapid cooling during the processing, which is equivalent to the quenching state. Therefore, the surface hardness of the steel fiber is relatively high. When used for concrete reinforcement and mixing, bending rarely occurs. If the steel fiber is too hard and brittle, It is also easy to break during stirring, affecting the reinforcement effect. When producing steel fibers by the melt extraction method, the steel fibers ejected centrifugally from the melt extraction wheel are still in a high temperature state and must be dispersed and cooled by rollers or vibration conveying methods. Otherwise, the steel fibers will gather and the heat will be difficult to dissipate, but it will have an annealing effect.

3: Corrosion resistance

As for the introduction of the corrosion resistance test of steel fiber concrete, it is known that in a humid environment, the concrete at the crack of the cracked steel fiber concrete component is carbonized, and the steel fibers in the carbonized area are corroded. The carbonization depth and degree of corrosion develop with time. For steel fiber concrete, the main use is the post-crack arc and post-crack toughness. Although the crack width is smaller than that of reinforced concrete, there are cracks after all. Therefore, anti-corrosion measures should be taken for steel fiber concrete used in humid environments, especially on the seashore. Tests have shown that, under the premise of ensuring that steel fiber concrete components have the same bearing capacity, the use of steel fibers with larger diameters can improve corrosion resistance. The use of steel fibers coated with epoxy resin or galvanized will improve corrosion resistance. If the construction process permits, this type of steel fiber can be used only in the 1-2 cm surface layer of concrete. Stainless steel fibers can also be used if necessary.

Company Address: No. 15A-06, Fukangcheng Economic Development Center Headquarters Building, No. 206 Longhui Road, Kunming Economic Development Zone, Yunnan Pilot Free Trade Zone

Mobile number:+86 13698775878

e-mail address: 339256382@qq.com