" />

" />【 WeChat QR code consultation 】

13698775878

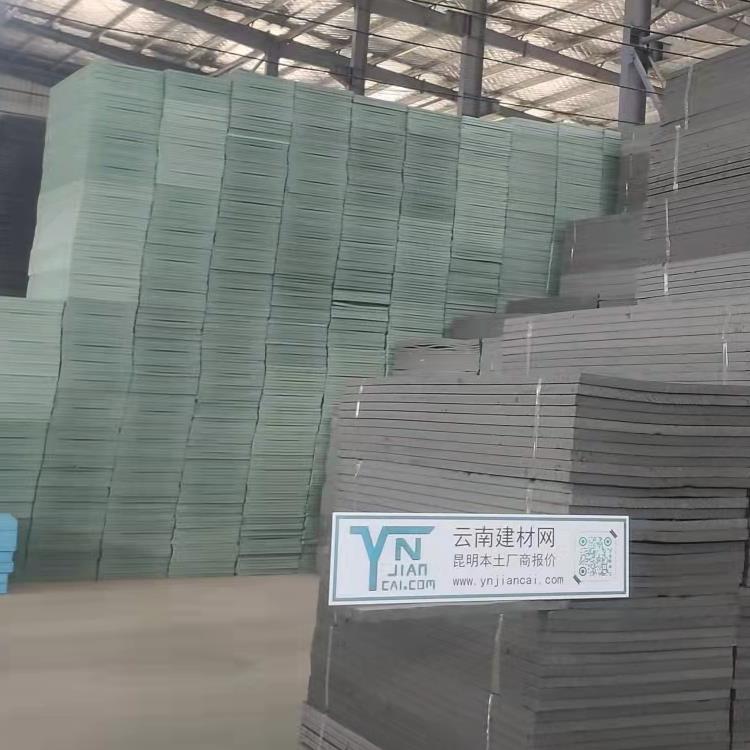

Extruded Polystyrene Board (XPS) is a material formed by a special continuous extrusion foaming process. Its surface forms a uniform and smooth hard membrane, and the internal structure is completely closed-cell, continuous, and evenly foamed in a honeycomb pattern. As a result, it has high compressive strength, light weight, water resistance, breathability, wear resistance, and is non-degradable.

Compared to EPS (Expanded Polystyrene) foam boards, XPS has significantly improved strength, thermal insulation, water vapor resistance, and other performance characteristics. Even under water immersion conditions, it can still maintain its thermal insulation and compressive strength, making it especially suitable for thermal insulation, moisture-proofing, and damp-proofing in buildings. It is one of the most cost-effective construction materials in the building industry today.

If you need customization, please select "Other" and specify your requirements in the remarks.

(1) **Unmatched Thermal Insulation Performance**

Its thermal conductivity is less than or equal to 0.028 W/mK, significantly lower than other insulation materials (in engineering, materials with thermal conductivity less than 0.25 W/mK are typically considered insulation materials). It features high thermal resistance and low linear expansion. It is widely used in roof insulation systems, cold storage, and internal and external wall insulation, providing exceptional results.

(2) **Impressive Water Resistance**

Water absorption rate is a crucial technical index for insulation materials. A high water absorption rate can reduce insulation performance. XPS boards feature a complete closed-cell structure, with no gaps on both sides of the board, preventing water leakage, condensation, freezing/thawing cycles, and moisture penetration. This effectively blocks water molecules from entering, preventing aging. Over time, this preserves the insulation layer, preventing the need for maintenance or replacement of the insulation structure. The closed-cell structure of XPS can effectively block the penetration of water molecules (including water vapor), ensuring long-lasting insulation.

(3) **Outstanding Long-Term Insulation Performance**

Low thermal conductivity is a key characteristic of all insulation materials. XPS boards are made from polystyrene (PS), which is already an excellent insulation material. The extrusion process and the dense closed-cell honeycomb structure further improve heat resistance, making XPS an outstanding choice for insulation.

(4) **Unexpected Compressive Strength**

XPS boards are lightweight, high-strength materials. With a density not exceeding 40 kg/m³, they can achieve a compressive strength of over 350 KPa. In buildings, they offer excellent impact resistance. Even when submerged in water, XPS boards retain their compressive strength, a feature not found in other insulation materials.

(5) **Good Fire Resistance**

We offer both standard and fire-retardant XPS products, which fully meet the fire resistance requirements for factories, sports venues, exhibition centers, and other applications.

(6) **High-Quality, Environmentally-Friendly Product**

XPS boards have stable chemical properties, no harmful volatile substances, and will not decompose or mold. They also offer excellent corrosion resistance. During production, environmentally-friendly raw materials are used, and no harmful gases are emitted. The solid waste produced is recyclable, making XPS a sustainable, eco-friendly product.

(7) **Easy Installation and Cost-Effective**

XPS boards are lightweight, making them easy to handle and cut without the need for electric saws. They are simple to fix using metal plates, wire, or polymer mortar, which helps reduce construction costs.

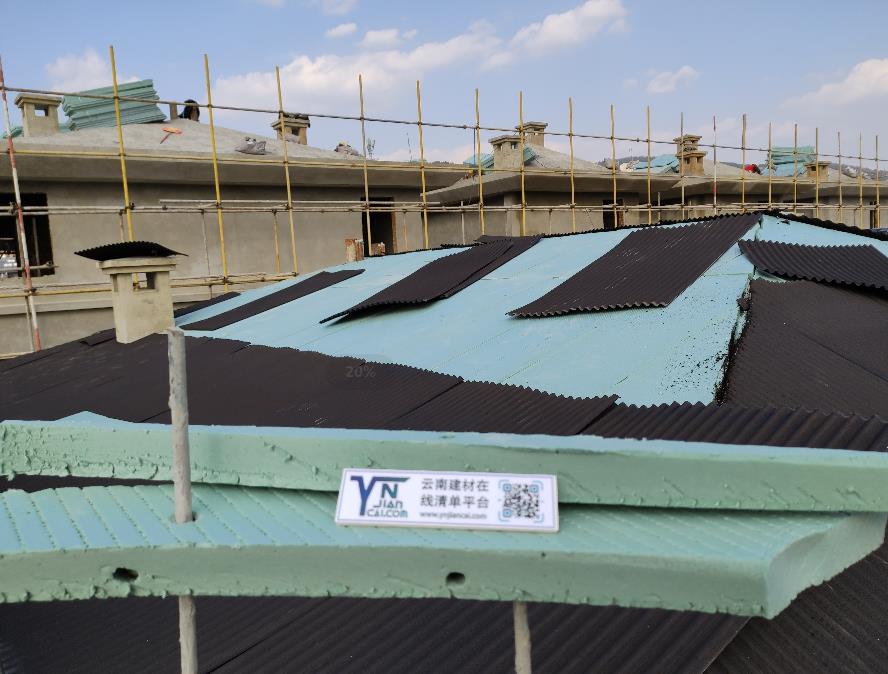

1> Widely used for wall insulation, flat concrete roofs, and steel structure roofs.

2> Used for moisture-proof insulation in low-temperature storage floors, parking platforms, airport runways, highways, etc.

XPS boards are made from polystyrene resin mixed with polymers, heated and catalyzed to form extruded, closed-cell foam panels. The internal structure consists of independent, sealed bubbles, offering excellent properties such as high compressive strength, low water absorption, moisture resistance, low permeability, light weight, corrosion resistance, long-term durability (nearly no aging), and low thermal conductivity. It is an environmentally friendly insulation material.

Extruded Polystyrene (XPS) boards are widely used for insulation in dry wall systems, flat concrete roofs, and steel structure roofs, as well as moisture-proof and insulating applications in low-temperature storage floors, underfloor heating pipes, parking platforms, airport runways, highways, etc. They are particularly effective in controlling ground frost heave. XPS boards are currently one of the most cost-effective and high-quality thermal insulation and moisture-proof materials in the construction industry.

1. Excellent and Long-Lasting Thermal Insulation Performance

The lowest possible thermal conductivity is a goal pursued by all insulation materials. XPS boards are primarily made from polystyrene, which is already an excellent low-conductivity material. The extrusion process further enhances this property by creating a dense honeycomb structure that effectively blocks heat transfer. The thermal conductivity of XPS boards is 0.028 W/m·K, providing high thermal resistance and low linear expansion. This is far lower than other insulation materials like EPS boards, foam polyurethane, insulation mortars, perlite, and others.

2. Superior Water Resistance and Moisture-Proofing

XPS boards feature a dense closed-cell structure. The molecular structure of polystyrene itself does not absorb water, and the boards are free from gaps on both sides. As a result, XPS boards have extremely low water absorption rates and excellent moisture and permeability resistance.

3. Corrosion Resistance and Durability

Unlike other rigid foam insulation materials that tend to age and lose performance due to water absorption over time, XPS boards are highly resistant to corrosion and aging. They maintain their insulation properties even under high water vapor pressure. XPS boards can last for 30-40 years, making them a long-lasting and reliable material for insulation applications.

Company Address: No. 15A-06, Fukangcheng Economic Development Center Headquarters Building, No. 206 Longhui Road, Kunming Economic Development Zone, Yunnan Pilot Free Trade Zone

Mobile number:+86 13698775878

e-mail address: 339256382@qq.com