The surface treatment of tray-type cable tray is divided into galvanizing and painting. Special anti-corrosion treatment can be applied in heavy corrosion environment.

The tray-type cable tray is equipped with a shield. If a shield is required, please indicate it when ordering or order according to the shield model. All its accessories are compatible with ladder-type and trough-type cable trays.

The maximum allowable uniformly distributed load and variables of tray-type cable trays at different spans.

Cable tray (cable bracket, cable tray ... Its overall fire resistance performance should meet the requirements of relevant national specifications or standards.

3. Aluminum alloy cable trays should not be used in places with high engineering fire protection requirements.

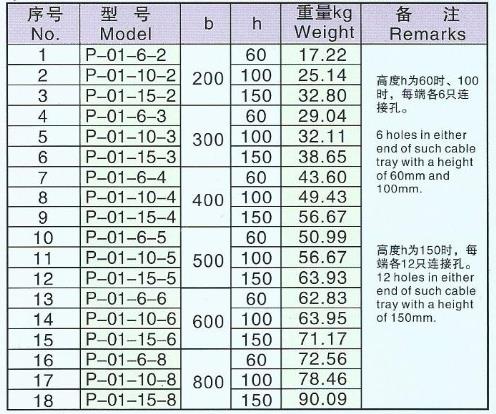

4. The selection of cable ladders and tray widths and heights should meet the requirements of the filling rate. Under normal circumstances, the filling rate of cable ladders and trays can be 40% to 50% for power cables and 50% to 70% for control cables, and 10% to 25% engineering development margin should be reserved.

5. When selecting the load level of the cable tray, the working uniformly distributed load of the cable tray should not be greater than the rated uniformly distributed load of the selected cable tray load level. If the actual span of the cable tray support bracket is not equal to 2m , the working uniformly distributed load should meet the requirements.

6. Under the condition of meeting the corresponding load, the specifications and dimensions of various components and supports and hangers should match the straight sections and bend series of trays and ladder racks.

7. When selecting the bend or lead-up and lead-down devices of the cable tray, it should not be less than the minimum allowable bending radius of the cable in the cable tray.

8. For steel cable trays with a span greater than 6m and aluminum alloy cable trays with a span greater than 2m or a load requirement greater than load grade D, the strength, stiffness and stability should be calculated or tested according to engineering conditions.

9. When several groups of cable trays are laid in parallel at the same height, the maintenance and inspection distance between adjacent cable trays should be considered.

10. For the commonly used specifications and dimensions of the width and height of steel trays and ladder racks, please refer to CESC31∶91 "Steel Cable Tray Engineering Design Specification" Section 2.2.2

11. For the commonly used specifications and dimensions of the width and height of aluminum alloy trays and ladder racks, please refer to Article 3.1.2 of CECS106∶2000 "Technical Specifications for Aluminum Alloy Cable Trays".

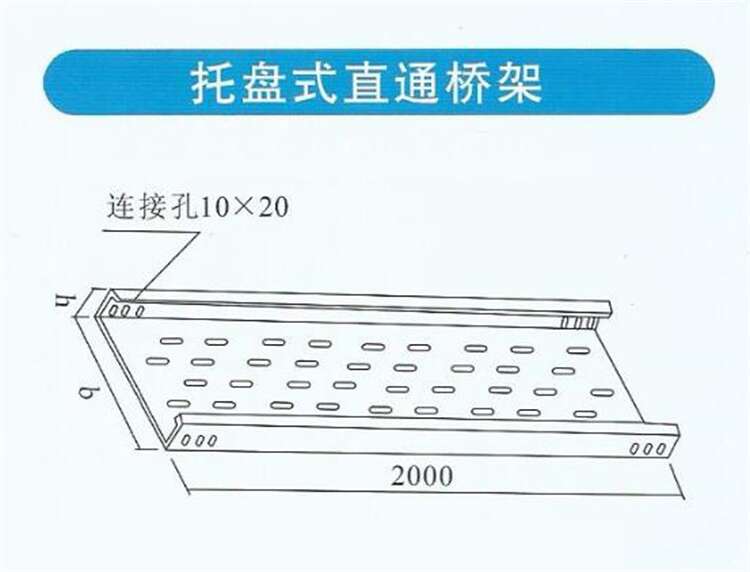

12. The standard length of a single piece of steel trays, ladder racks and aluminum alloy trays and ladder racks can be 2, 3, 4, and 6 meters.

13. For the surface anti-corrosion treatment method of steel cable trays, please refer to Article 3.4.2 of CECS31∶91 "Design Specifications for Steel Cable Tray Engineering".

14. For the surface anti-corrosion treatment method of aluminum alloy cable trays, please refer to Table 4.4.1 of CECS 106∶2000 "Technical Specifications for Aluminum Alloy Cable Trays". .

Key points for construction and installation

① The laying direction of cable trays and cable ducts should be short and should be laid along walls, columns or beams as much as possible.

② According to the laying direction of cable trays and cable ducts, the required embedded steel plate position and load should be proposed to the civil engineering and structural professionals for reserved wall holes, floor holes and hanger installation. And it should be coordinated with the process, plumbing and power professionals.

③ When designing the concealed metal cable duct wiring in the ground, close cooperation should be made with the civil engineering professionals so as to reasonably determine the line path and equipment selection according to different structural types and building layouts.

④ Cables of different voltages and different uses should not be laid in the same cable tray:

5. When the installation or maintenance does not need to consider additional concentrated loads under engineering conditions, the working uniform load of the cable ladder and tray is calculated according to the uniform distribution of the cable deadweight.

6. The cable tray should not be laid parallel to the following pipelines. When it cannot be avoided, the location of the cable tray should comply with the following regulations, or corresponding protective measures should be taken.

(1. Cable trays should be above corrosive liquid pipelines.

(2. Cable trays should be below thermal pipelines.

(3. When flammable and explosive gases are heavier than air, cable trays should be above the pipelines.

(4. When flammable and explosive gases are lighter than air, cable trays should be below the pipelines.

7. For the minimum distance between cable trays and pipelines, see relevant standards.

8. The necessary distance should be maintained between the integrated wiring cables and nearby electrical equipment such as motors and power transformers that may generate high-level electromagnetic interference. The distance between the integrated wiring cables and power cables should comply with the provisions of Article 11.0.2 of GB/T 50311-2000.

9. The distance between the integrated wiring cables, optical cables and pipelines laid on the wall and other pipelines should comply with the provisions of Article 11.0.2 of GB/T 50311-2000. 10. When laying cable trays horizontally, the optimal span should be selected according to the load curve for support, and the span is generally 1.5 to 3.0 meters. When laying cable trays vertically, the fixed spacing should not be greater than 2 meters.

" />

" />