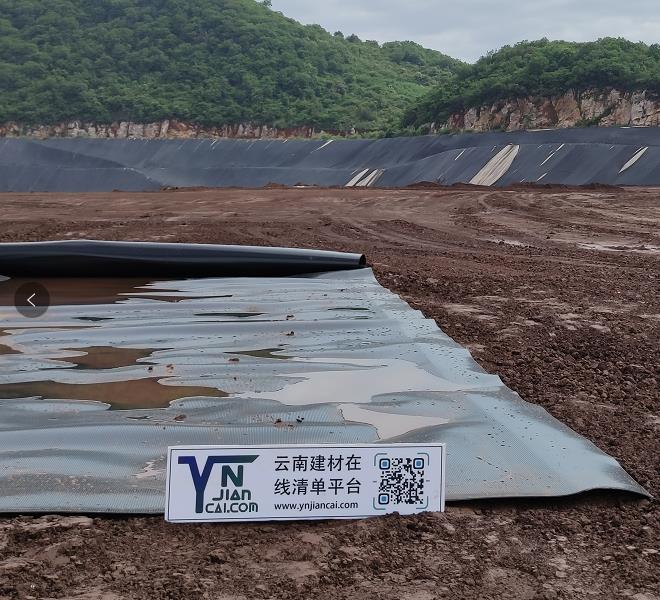

For mining areas, the construction of geomembranes is relatively strict. From the sampling inspection of materials just entering the factory, to the inspection of welding seams, to the inspection of air tightness, there are a series of strict requirements for all links. The construction site this time is located in Matang Industrial Park, Wenshan Prefecture, Yunnan Province. It is a mining company's slag treatment tailings, which we usually call tailings dams. The construction of geomembranes in tailings dams is related to ecology and environmental protection. Problems will directly affect the surrounding human and livestock water and agricultural land, because slag contains a lot of chemical substances. It can be said that there is almost no grass where there are slags.

The tailings under construction are additional items, that is, they are raised on the basis of the original anti-seepage. The total amount of geomembranes used in the construction is 20,000 square meters, and the total amount of geomembranes is 4,000 square meters. At the beginning of the site, our company conducted relevant construction docking with Party A, from the on-site storage of materials to the deployment of construction personnel, whether mechanical auxiliary construction is required? The required personnel tools and related requirements have been docked in detail.

The laying site is mainly based on the slope, and the laying site is a steep slope, which is dangerous. Therefore, safety ropes, rope ladders and other tools are also equipped for construction workers. The most difficult part of geomembrane construction is the movement of the membrane material, because the weight of a roll of membrane material is about 600 kilograms. Therefore, we welded a bracket for this situation and used the bracket to retract and release the geomembrane.

After more than a month of intense construction, we successfully completed the construction and welding of the geomembrane on the entire construction site. We also actively cooperated with the later acceptance and on-site data.

" />

" />