Aluminum silicate board mainly uses aluminum silicate as the raw material. As an environmentally friendly inorganic material, it not only has excellent soundproofing properties but also is highly heat-resistant and has good waterproof performance. The aluminum silicate board can shrink freely, has excellent wind and pressure resistance, and is lightweight, making it easy to transport and install. Its strong adhesion greatly improves construction efficiency.

Aluminum silicate board has excellent thermal insulation performance. Due to its stable internal structure and high bonding strength, it significantly improves construction efficiency during the installation process and is not affected by external stability. It is suitable for both indoor and outdoor spaces. If central air conditioning is installed indoors, it can effectively maintain insulation, reduce energy loss, and meet relevant national industry standards.

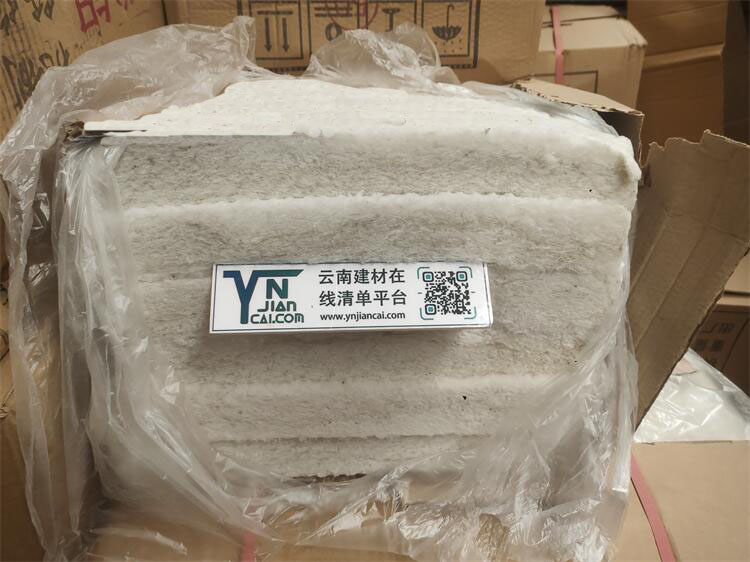

In the production process of aluminum silicate board, the best quality stone materials are selected. Under high temperatures, the materials undergo special technical treatments, and the appropriate amount of additives is added to form the board through heating. The aluminum silicate board also contains fiber materials, which greatly meet the standards for building materials in the real estate industry. The strict material ratio ensures the formation of a unique insulation layer on the wall.

Aluminum silicate board not only has good insulation performance but also stands out in terms of fire resistance, meeting the standards for all external wall requirements in modern decoration. The materials used have inherent non-combustibility and high-temperature resistance, giving the board advantages that traditional materials cannot match. It is frequently used in many fireproof door products, mainly as internal filler to enhance fire resistance.

" />

" />